With digital transformation, the manufacturing sector must redefine not only its machinery but also its human capital. Today, competitive advantage comes not just from physical labour but also from employees with digital skills. Yet a major problem persists:

Tacit knowledge disappears as experienced staff retire.

New-generation employees possess technical backgrounds but lack plant-specific process know-how.

Training is largely theoretical, and workers cannot access the information they need on the shop floor in real time.

A knowledge gap grows between blue-collar operators and technical teams.

The result? Productivity drops, error rates rise, and ramp-up periods lengthen.

Challenge: Knowledge Locked to Individuals and Lack of Real-Time Training Support

Key issues on the manufacturing floor include:

New hires learn processes through trial-and-error.

Instructions on how to replace a component exist only in a supervisor’s memory.

Technical documents are outdated or hard to reach.

Continuous training is costly, and creating up-to-date content is difficult.

Shop-floor personnel have virtually no way to obtain information while working.

At this point, LLM-based AI assistants provide one-on-one support to the workforce, transforming the process.

Solution: Instant Knowledge Access and Enterprise Memory Support with SkyStudio

SkyStudio offers employees a personalised, interactive knowledge advisor built on the company’s internal procedures, training documents, and technical content. This enables:

New employees learn on the job

A worker performing maintenance can ask SkyStudio:

“Which part should I inspect during a hydraulic-piston failure?”

Answer:

“In seven similar incidents, the valve body was faulty. Steps: 1) Depressurise the system, 2) Remove the valve …”

Learning from internal documents, not memory

Every SkyStudio response is backed by company content—no fabricated data. Each answer cites its source, e.g., “Reference: Pneumatic Failure Instruction v2.pdf”.

Faster training, lower costs

SkyStudio can host custom training guides, Q&A modules, and task-based content for employees.

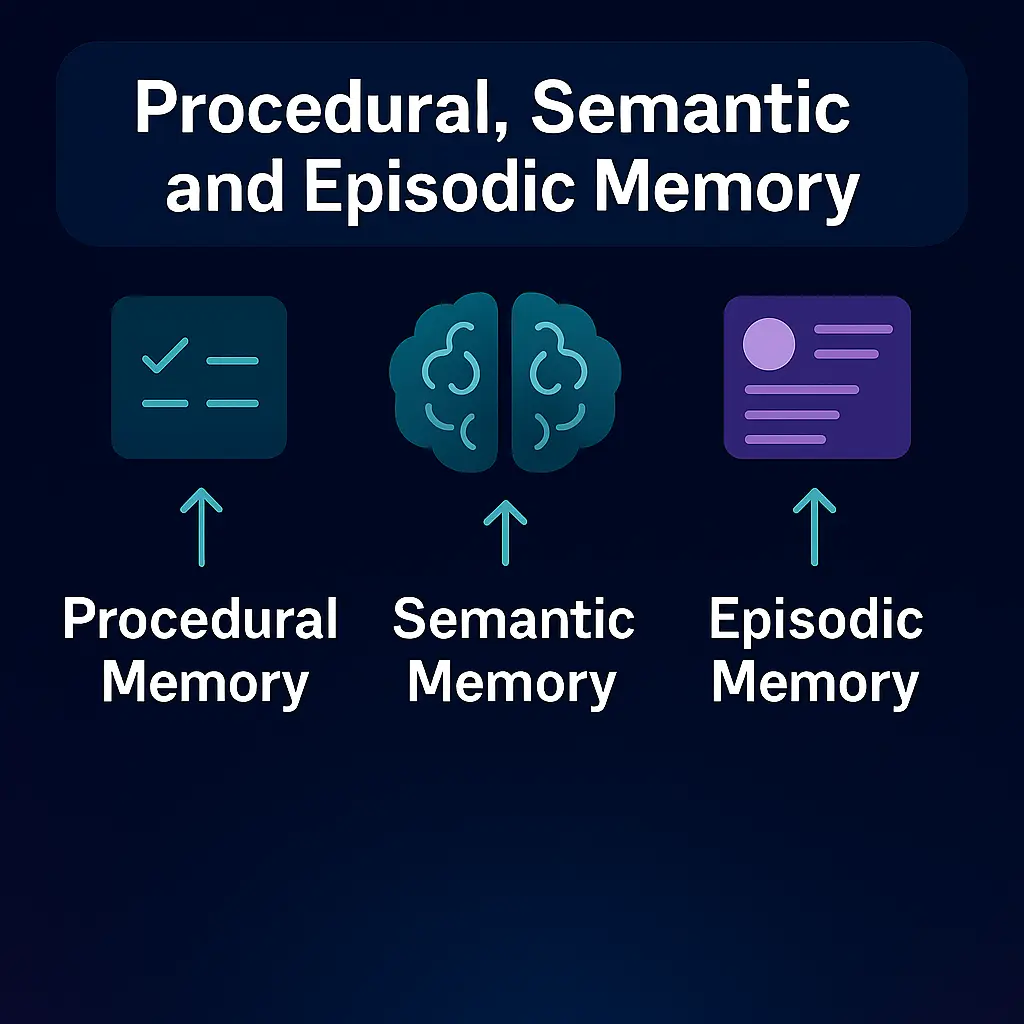

Institutionalising tacit knowledge

The supervisor’s expertise is no longer confined to one person. Examples, documents, and past intervention records uploaded to SkyStudio make knowledge independent of individuals.

Managerial insight

SkyStudio can report the most frequent questions, recurring issues, and missing procedures to management, enabling data-driven training decisions.